Electrical contractors, OEMs, and panel builders across Ontario often face the same challenge — every project demands something unique, but standard enclosures rarely come ready to install. Whether you’re building automation panels for a food processing facility, retrofitting controls in a wastewater plant, or engineering OEM power systems, on-site modifications add time, cost, and risk.

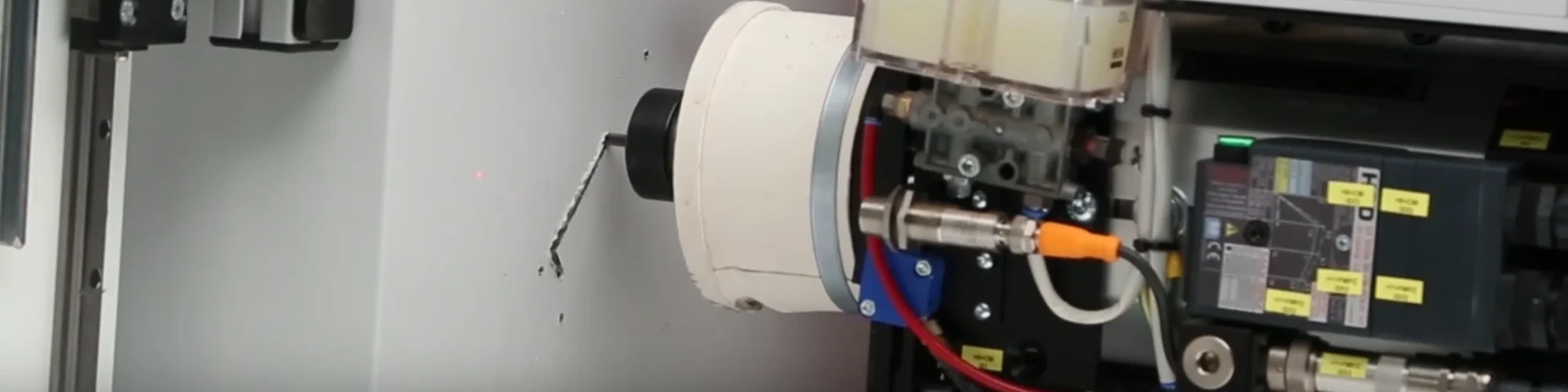

That’s why Province Electric Supply invested in an official nVent HOFFMAN Mod Center — a state-of-the-art, CNC-driven machining system designed to deliver custom, ready-to-install enclosures with certified precision, speed, and consistency.

The Challenge with Standard Enclosures

Most electrical enclosures arrive unmodified. Cutting, drilling, or punching on-site often leads to misalignment, surface damage, or even voided UL and NEMA certifications. Contractors lose valuable time waiting for fabrication or making manual corrections that can slow down installation schedules.

Common pain points include:

- Lost productivity due to manual fabrication or rework

- Inconsistent results from field modifications

- Delays caused by outsourcing to third-party fabricators

- Certification issues when modifications are performed without proper equipment

Province’s nVent HOFFMAN Mod Center eliminates these issues by providing certified, precision-cut enclosures that arrive ready to wire and mount — helping Ontario professionals meet deadlines and maintain compliance.

What Makes the nVent HOFFMAN Mod Center Different

The Mod Center isn’t just another fabrication tool — it’s engineered by nVent HOFFMAN specifically for certified enclosure customization. Using advanced CNC-guided drilling, tapping, and milling, Province’s team delivers repeatable, error-free modifications on steel, stainless-steel, or aluminum enclosures while maintaining manufacturer tolerances and certifications.

Key advantages include:

- nVent HOFFMAN certified machining for accuracy and compliance

- CNC precision that guarantees consistent, high-quality results

- Compatible with most standard enclosure models and materials

- Fast turnaround through Province’s local Ontario Mod Center

Every modification is verified to maintain integrity and preserve original certification compliance.

What Can Be Customized

Province’s nVent HOFFMAN Mod Center supports nearly any enclosure requirement — from industrial control panels to automation systems and utility cabinets.

You can customize:

- Pushbutton and indicator cutouts

- Touchscreen and HMI window openings

- Conduit knockouts and cable entries

- Fan, vent, and thermal management openings

- Mounting patterns, DIN rails, and brackets

- Tapping, labeling, and pattern alignment

- Backplate drilling and tapping for faster component installation — backplates can be pre-machined before wiring begins, allowing internal components to be installed quickly and accurately

Each project is completed with CNC-guided precision, ensuring your enclosures arrive clean, accurate, and ready to install — no on-site cutting required.

The Benefits for Ontario’s Electrical Professionals

- Save Time: Skip on-site cutting and drilling. Enclosures arrive ready to wire.

- Reduce Labor Costs: Your crew focuses on installation, not fabrication.

- Stay Certified: All modifications performed under nVent HOFFMAN’s certification framework.

- Ensure Precision: CNC machining delivers perfect alignment every time.

- Accelerate Projects: Local facility means shorter lead times and consistent results.

For OEMs and panel builders, this means faster prototyping and scalable production runs.

For contractors in industries such as water and wastewater, mining, and manufacturing, it means reliable enclosures that fit perfectly — the first time.

Integrated Solutions for Ontario Industries

From food and beverage automation to energy infrastructure and renewable systems, the nVent HOFFMAN Mod Center supports diverse Ontario industries with faster, safer, and more efficient custom enclosures.

- Industrial OEMs and Panel Builders: Precision machining for repeatable, high-volume builds.

- Utilities and Energy: Certified cutouts for conduit, sensors, and cooling in field applications.

- Automation and MRO Teams: Rapid retrofits for smart systems and maintenance upgrades.

Combined with Province’s expertise in electrical enclosures, thermal management, and project services, your equipment is fully supported from design through installation.

Why Choose Province Electric Supply

- Authorized nVent HOFFMAN Mod Center partner serving Ontario

- Local machining and technical support for faster turnaround

- Certified precision that preserves UL/NEMA compliance and warranty

- Design assistance from experienced enclosure specialists

- Seamless integration with other services like Smart Inventory Management and Project Services

Province combines nVent HOFFMAN engineering technology with local expertise, helping customers in automation, utilities, and industrial sectors complete projects faster and more efficiently.

Ready to Simplify Your Next Project?

Stop spending valuable time modifying enclosures on-site.

Contact Province Electric Supply to request a quote or upload your custom enclosure drawing.

Our nVent HOFFMAN Mod Center delivers the precision, speed, and certified quality Ontario professionals rely on.

FAQ

Q: What is the nVent HOFFMAN Mod Center?

A: It is a certified CNC machining system that customizes electrical enclosures with precise cutouts, drilling, tapping, and milling while maintaining manufacturer certifications.

Q: Why should I use the Mod Center instead of modifying enclosures on-site?

A: On-site modifications can cause misalignment, surface damage, and loss of NEMA/UL certification. The Mod Center delivers accurate, clean machining that arrives installation-ready.

Q: What types of modifications can be done?

A: The Mod Center supports pushbutton cutouts, HMI openings, conduit entries, fan and vent openings, DIN rail patterns, labeling, and full backplate drilling and tapping.

Q: Does Mod Center machining affect UL or NEMA certifications?

A: No. All work is performed under nVent HOFFMAN’s certified process, which maintains the enclosure’s original compliance and warranty.

Q: Can Province modify stainless-steel or aluminum enclosures?

A: Yes. The Mod Center handles steel, stainless steel, and aluminum enclosures from nVent HOFFMAN and most other standard enclosure models.

Q: How quickly can custom enclosures be completed?

A: Turnaround is typically a few business days depending on complexity, with faster timelines possible for repeat or high-volume programs.

Q: Can I submit my own layout or drawing?

A: Yes. You can upload your drawings, templates, or measurements, and the Mod Center team will machine the enclosure to match your exact specifications.